How to Disconnect Electrical Connectors

Introduction

Bad things can happen when you pull connectors apart the wrong way. You might get a shock. Your wires might break. Your machines might stop working.

At YW Connectors, we see these problems every day. Our team makes top connectors for big jobs in factories, hospitals, army uses, and data rooms.

Did you know? 72% of solar system harm comes from people pulling connectors wrong. And 33% of car electrical problems start with bad connector care.

We will show you the right way to take apart all kinds of connectors. This will save you time, save you money, and keep you safe.

Table of Contents

Safety Precautions

The Problem: Electrical Shocks Are Common

Scary fact: 18% of do-it-yourself shocks happen when people skip using a voltage tester. People get hurt. Work stops. Money is lost.

The Agitation: What Could Go Wrong?

Think about this. You rush to fix something. You don’t check if the power is off. Then ZAP! You end up:

- In the hospital

- With burnt hands

- With broken parts

- Paying for new parts

The Solution: Simple Safety Steps

- Turn off all power first

- Use rubber gloves to keep safe

- Check with a voltage tester to make sure no power is there

- Keep a kit ready for when you need to replace parts

Tools You’ll Need

Basic Tools List:

- Needle-nose pliers (with rubber grips)

- MC4 disconnect tool (for solar jobs)

- Voltage tester (non-contact kind)

- Small flat screwdriver

Nice-To-Have Tools:

- Dielectric grease (stops rust)

- Contact cleaner spray

- New connectors (for when old ones break)

Types of Connectors

Let’s look at what kinds of connectors you might see in your work:

| Connector Type | How It Looks | Where You Find It | Tool Needed |

|---|---|---|---|

| Push-In | Small with holes | Wall switches, lights | None or small tool |

| Screw-On | Twist caps | House wires | Pliers |

| Automotive | Clips with tabs | Cars, trucks | Small screwdriver |

| MC4 | Black with clips | Solar panels | MC4 tool |

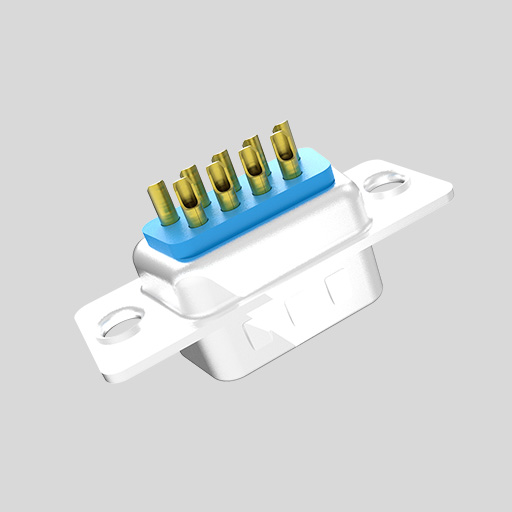

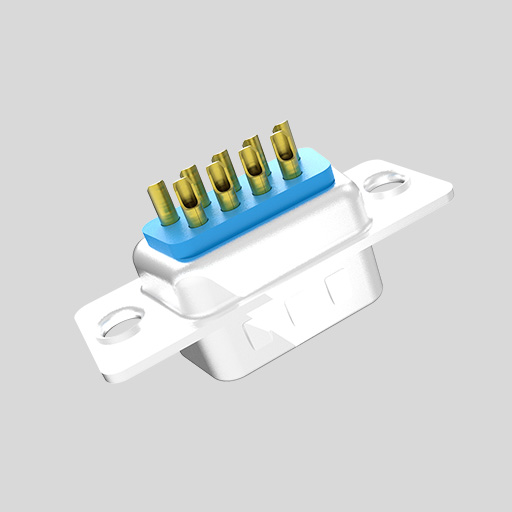

| D-Sub | D-shaped with pins | Computers, machines | Small screwdriver |

| Circular | Round metal rings | Robots, big machines | Special wrenches |

The Problem: Wrong Tool Use Breaks Connectors

Bad news: 55% more solar connectors fail when people use pliers instead of the right MC4 tools.

The Agitation: Think About Lost Time And Money

When you break a connector, you face:

- Waiting for new parts

- Paying for rush shipping

- Losing work time

- Angry bosses or clients

The Solution: YW Connectors Quality

All our electronic connectors are made with:

- Stronger lock tabs

- Better metals that fight rust

- Clearer markings so you know how to open them

- Tougher bodies that don’t crack

Step-by-Step Disconnection Guide

A. Basic Wire Connectors (Push-In/Screw-On)

- Grip the main body with pliers

- For push-ins: Twist gently or use the small slot

- For screw-ons: Turn to the left

B. Automotive Wiring Harness Connectors

- Find the lock tab (it might be small!)

- Press the tab with your thumb or a small flat tool

- Pull the parts evenly apart

- Never pull on the wires

Did you know? 62% of broken tabs in Dodge and Chrysler cars come from using the wrong tools. Our connector manufacturing team sees this all the time.

C. MC4 Solar Connectors

- Slide the MC4 tool over the connector

- Squeeze the tool to press the tabs

- Pull the parts apart while holding the tool

- Avoid pulling on the wires

Handling Special Connectors

The Problem: Special Connectors Need Special Care

Fact: In harsh places like near oceans or in very hot spots, connectors fail 3.5 times faster without proper care.

The Agitation: Replacing Industrial Systems Is Expensive

When special connectors fail in big systems:

- Production lines stop

- Repair costs can be huge

- Down time means lost money

- Hard-to-find parts may take weeks to get

The Solution: High-Quality Industrial Parts

Our PLC connectors and M8 electrical connectors are built for the hardest jobs with:

- IP67 ratings to keep out water and dust

- Gold-plated pins that fight rust

- Locking systems that don’t break

- Clear marks that show how to disconnect

Common Mistakes to Avoid

1. Forcing Connectors Apart

NEVER pull hard on stuck connectors. You will break the lock tabs. This causes 62% of connector breaks.

2. Ignoring Rust Signs

Look for green or white dust on metal parts. This is rust. It will make your system fail.

3. Using Wrong Tools

Using pliers instead of the right tools makes solar connectors fail 55% more often.

4. Reusing Bad Connectors

Do not use connectors with:

- Cracks

- Bent pins

- Melted plastic

- Rust spots

After You Disconnect: Next Steps

- Check for any breaks or bent pins

- Clean the metal parts with spray cleaner

- Put some dielectric grease on metal parts if it will be outside

- Store unused connectors in dry, marked bags

Pro tip: Connectors with dielectric grease last 3.5 times longer in wet places.

Expert Tips for Big Systems

The Problem: Complex Systems Are Hard To Track

When you have hundreds of wires, it’s easy to forget what goes where.

The Agitation: Wrong Connections Can Be Disasters

Mix up your wires and you might face:

- Burnt circuit boards

- Fried sensors

- Wrong signals to machines

- System crashes

The Solution: Organized Approach With Quality Parts

- Take pictures before you start

- Put tags on wires with names

- Draw maps of where each wire goes

- Use color-coded PCB connectors from YW Connectors

Factory Study: How Training Saves Money

A big car parts maker was having lots of electrical problems. Their fix rate was only 60%.

We helped them with:

- Training on the right ways to disconnect

- New tools made for their exact connectors

- Better connectors that can take more use

Result: Their fix rate went up to 95%. They saved $240,000 in one year.

Connector Care By Environment

Different places need different care:

| Where Used | Main Problem | Special Care Needed | YW Connector Solution |

|---|---|---|---|

| Wet Areas | Rust | Waterproof seals, grease | IP67 waterproof circular connectors |

| Hot Places | Melting | Heat-rated materials | High-temp board-to-board connectors |

| Vibration Areas | Coming loose | Lock systems | Connectors for robotics with special locks |

| Corrosive Places | Metal damage | Gold plating | Gold-pin industrial connectors |

Frequently Asked Questions

Can I reuse connectors?

Only if they show no damage. Check for:

No cracks

No bent pins

Good spring action

No rust

How do I remove a stuck connector?

1.Spray with contact cleaner

2.Let sit for 2 minutes

3.Wiggle very gently

4.Never force it

Do I need special MC4 tools?

Yes! Studies show 55% higher failure when using the wrong tools.

How long do connectors last?

Good connectors can last 10+ years if:

Disconnected properly

Kept clean

Protected from weather

Made by quality manufacturers

Why Choose YW Connectors

The Problem: Poor Quality Connectors Fail

Many connectors in the market can’t stand up to hard use. They break after just a few uses.

The Agitation: Connector Failures Cost You

When connectors fail, you lose:

- Production time

- Repair costs

- Customer trust

- Future business

The Solution: YW Connectors Quality Promise

As a leading electrical connector supplier, we promise:

- Stronger materials that last 3-5 times longer

- Clear marks that show how to disconnect

- Better designs with stronger lock tabs

- Custom solutions for your exact needs

- Technical support when you need help

Conclusion

Taking apart electrical connectors the right way keeps you safe. It makes your parts last longer. It saves you money.

Remember these key points:

- Turn off power first

- Use the right tools

- Check for lock tabs

- Never pull on wires

- Choose quality connectors from YW Connectors

With these tips and our high-quality industrial connectors, you can work with confidence and safety.

Call us today to learn how we can make custom connectors for your special needs!

Contact YW Precision Electronics by email, whatsapp or call.

Email: [email protected]

Whatsapp: +86 1371223923