-

Henggang Industrial Park, 518173

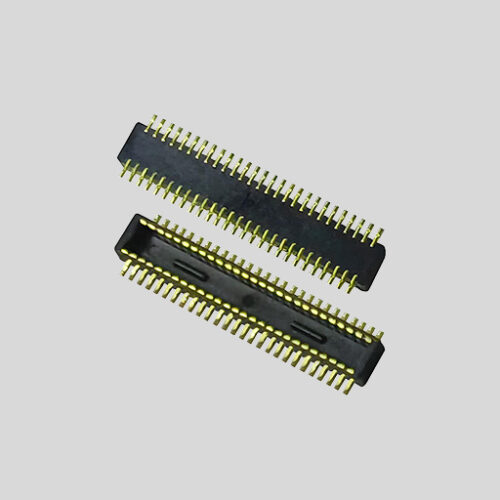

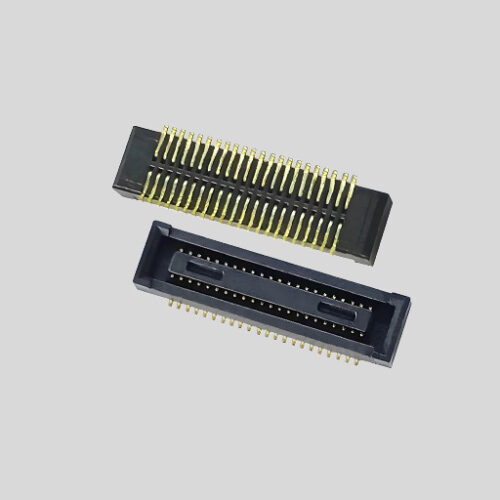

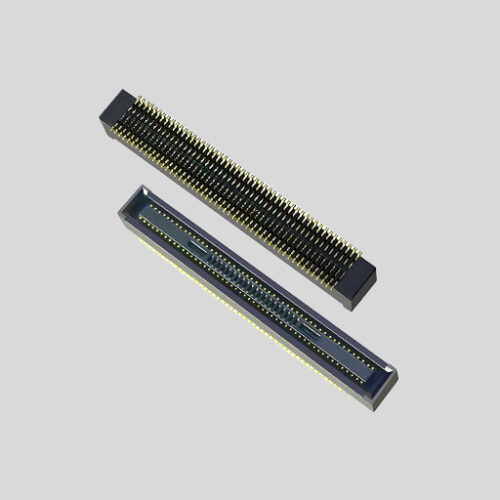

0.4 mm pitch board to board connector high quality 100 pos

Part Number: YWH40-BS1002900

| Part NO | YWH44-BS1002900 | Stacking Height | 3.0mm |

| Rated Current | 0.3A | Rated Voltage | 50V AC/DC |

| Position | 100 pin connectors | Contact Resistance | 90mΩ Max. |

| Operating Temperature | -55 to +85℃ | Mating Durability | 30 cycles |

0.4 mm pitch board to board connector high quality 100 pos

YW Precision Electronics is a trusted and experienced OEM/ODM high quality electronic connectors factory in China.

You can contact us for board to board, wire to board, wire to wire connectors used for Industrial automation and control, medical, telecommunication and military fields.

YWH40 Series 0.4 mm pitch board to board connector Table

| PART NO. | NO.of Pos. | DIMA | DIM B | DIM C | DIMD |

| YWH40-BS0102900 | 10 | 4.60 | 1.60 | 一 | 1.00 |

| YWH40-BS0122900 | 12 | 5.00 | 2.00 | 一 | 1.00 |

| YWH40-BS0202900 | 20 | 6.60 | 3.60 | 1.93 | 1.00 |

| YWH40-BS0242900 | 24 | 7.40 | 4.40 | 2.43 | 1.20 |

| YWH40-BS0302900 | 30 | 8.60 | 5.60 | 3.18 | 1.50 |

| YWH40-BS0342900 | 34 | 9.40 | 6.40 | 3.68 | 2.30 |

| YWH40-BS0402900 | 40 | 10.60 | 7.60 | 5.08 | 3.20 |

| YWH40-BS0442900 | 44 | 11.40 | 8.40 | 5.86 | 3.20 |

| YWH40-BS0502900 | 50 | 12.60 | 9.60 | 5.50 | 3.20 |

| YWH40-BS0602900 | 60 | 14.60 | 11.60 | 6.00 | 3.20 |

| YWH40-BS0/02900 | 70 | 16.60 | 13.60 | 7.00 | 3.20 |

| YWH40-BS0802900 | 80 | 18.60 | 15.60 | 8.00 | 3.20 |

| YWH40-BS0902900 | 90 | 20.60 | 17.60 | 9.00 | 3.20 |

| YWH40-BS1002900 | 100 | 22.60 | 19.60 | 10.00 | 3.20 |

| YWH40-BS1202900 | 120 | 26.60 | 23.60 | 14.00 | 3.20 |

Basic data for 100 pin 0.4 mm pitch board to board connector

| Series: | YWH40 | Connector Type: | Board to Board |

| Min Operating Temperature: | -55 C | Mount: | Surface Mount |

| Gender: | Female, Socket | Contact Plating: | Gold |

| Orientation: | Straight | Termination: | SMD/SMT |

| Pitch: | 0.4 mm | Number of Rows: | 2 |

| Voltage Rating: | 50 V | Max Operating Temperature: | 85 C |

| Withstanding Voltage | 150V AC for 1 min. | Insulation Resistance | 50MΩ Min. (100V DC) |

| Temperature Cycles | Contact Resistance:90m Ω Max. Insulation Resistance:50M Ω Min. | ||

- RoHS

- REACH

- Low-Halogen

Q: What are the eight Connector Technology Trends in 2025?

A: Connectors may not be the most visible components, but they are the heroes of modern electronic devices, playing a major role in the performance, reliability, and functionality of devices. We are witnessing a wave of innovation in connector development, driven by the growing demand for miniaturization, high-speed data transmission, and high reliability.

Below are eight major connector trends and showcases for your reference.

1. Miniaturization and High Density

As devices continue to become more compact and feature-rich, there is a growing demand for smaller connectors that can handle higher pin densities without compromising performance. Miniaturization enables the design of slimmer, more portable devices, while high-density connectors enable more complex circuits to be implemented in limited space.

Click this link for 0.4 mm pitch board to board connector

2. High-Speed Data Transfer

With the increasing use of high-speed communication protocols, the demand for connectors that support faster data rates while minimizing signal loss is also increasing. Such high-speed data connectors are commonly used in computing, networking, and multimedia applications.

3. Flexible and Stretchable Connectors

Flexible and stretchable connectors are designed to bend, twist, and stretch without losing their functionality, making them game changers in healthcare, wearables, and flexible electronics.

4. Wireless and contactless connectivity

Integrating wireless and near-field communication (NFC) technology into connectors reduces the need for physical electrical contact, enabling new applications in medical devices and consumer electronics.

5. Smart connectors

Incorporating smart features—like built-in diagnostics, monitoring capabilities, and data analytics—into connectors can improve performance and enable applications such as predictive maintenance, machine identification, energy measurement, and surge protection. Smart connectors are able to provide real-time information about the status of the connection, environmental conditions, and potential problems, which is pretty cool and adds value to many applications.

6. Power and Signal Integration

Combining power and data transmission in a single connector simplifies design and reduces the number of components required. This approach is most valuable in compact and lightweight device designs where space is at a premium.

7. Ruggedness and Reliability

Connectors for industrial and automotive applications must be able to withstand harsh environments, including extreme temperatures, vibration, and exposure to moisture. Enhanced connector ruggedness and reliability ensure long-term performance and reduce the risk of critical system fai

8. Modular and Configurable Designs

Modular connectors offer customization and flexibility. They are valuable in industrial automation and data center environments because they simplify maintenance and upgrades by making the connection interface easily configurable and reconfigurable.

Looking to the Future

Designers and engineers striving to improve device performance and functionality must keep up with emerging connector trends. From miniaturization and high-speed data transmission to smart technologies and stretchable materials, innovations in connector technology are driving advancements in many applications. From sensors in wearable devices to high-speed data lines in our supercomputers, connectors are the hidden heroes of our digital lives.

Pls feel freely to contact us –your reliable and high quality 0.4 mm pitch board to board connector manufacturer.

Leave your any message below, you will get our reply within 30mins.

| Connector system | Board to board |

|---|---|

| Operating Voltage (VDC max) | 50V |

| Pitch | 0.4 |

| Current (MAX) | 0.3A |

| Termination Interface Style | SMD |